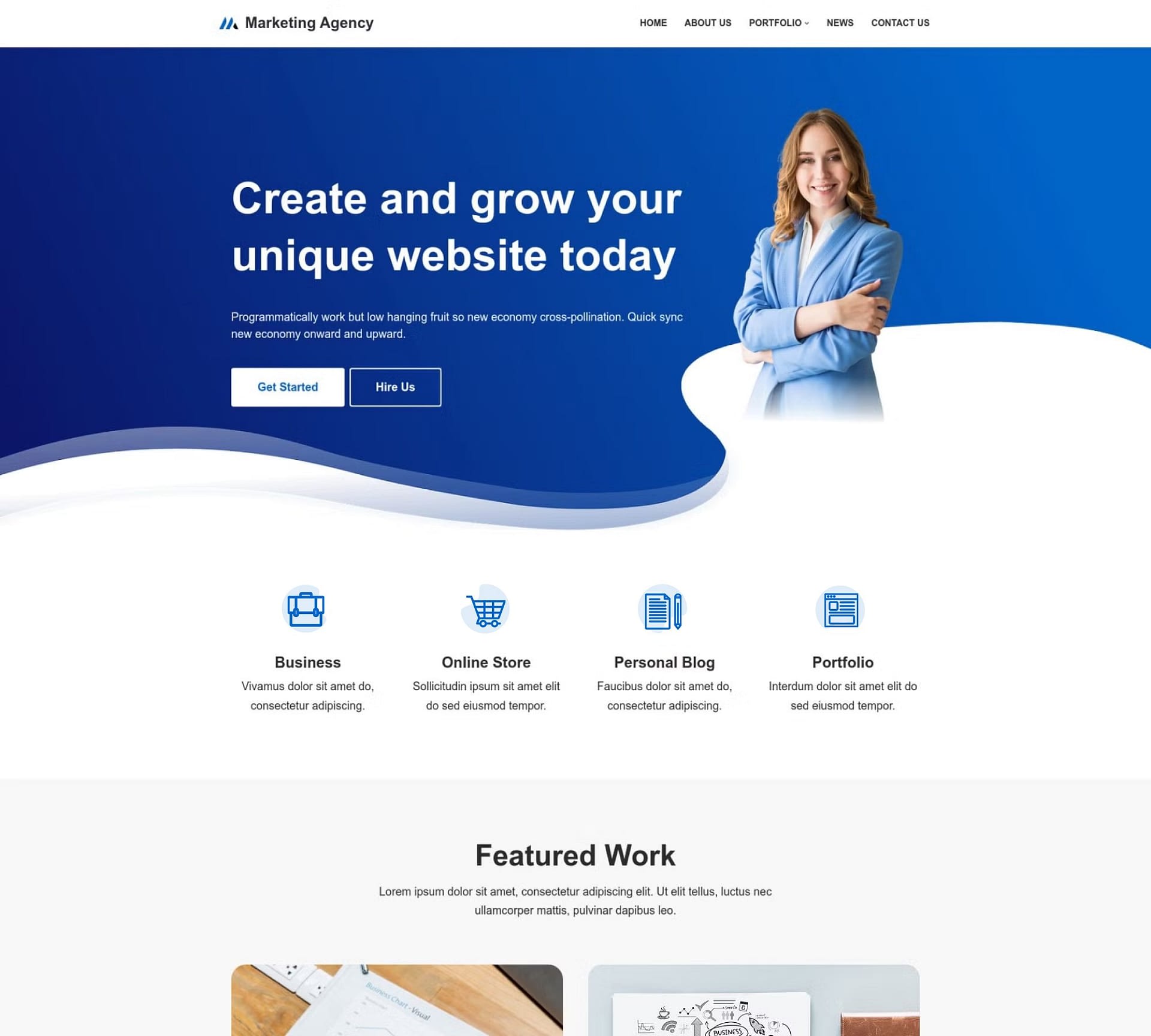

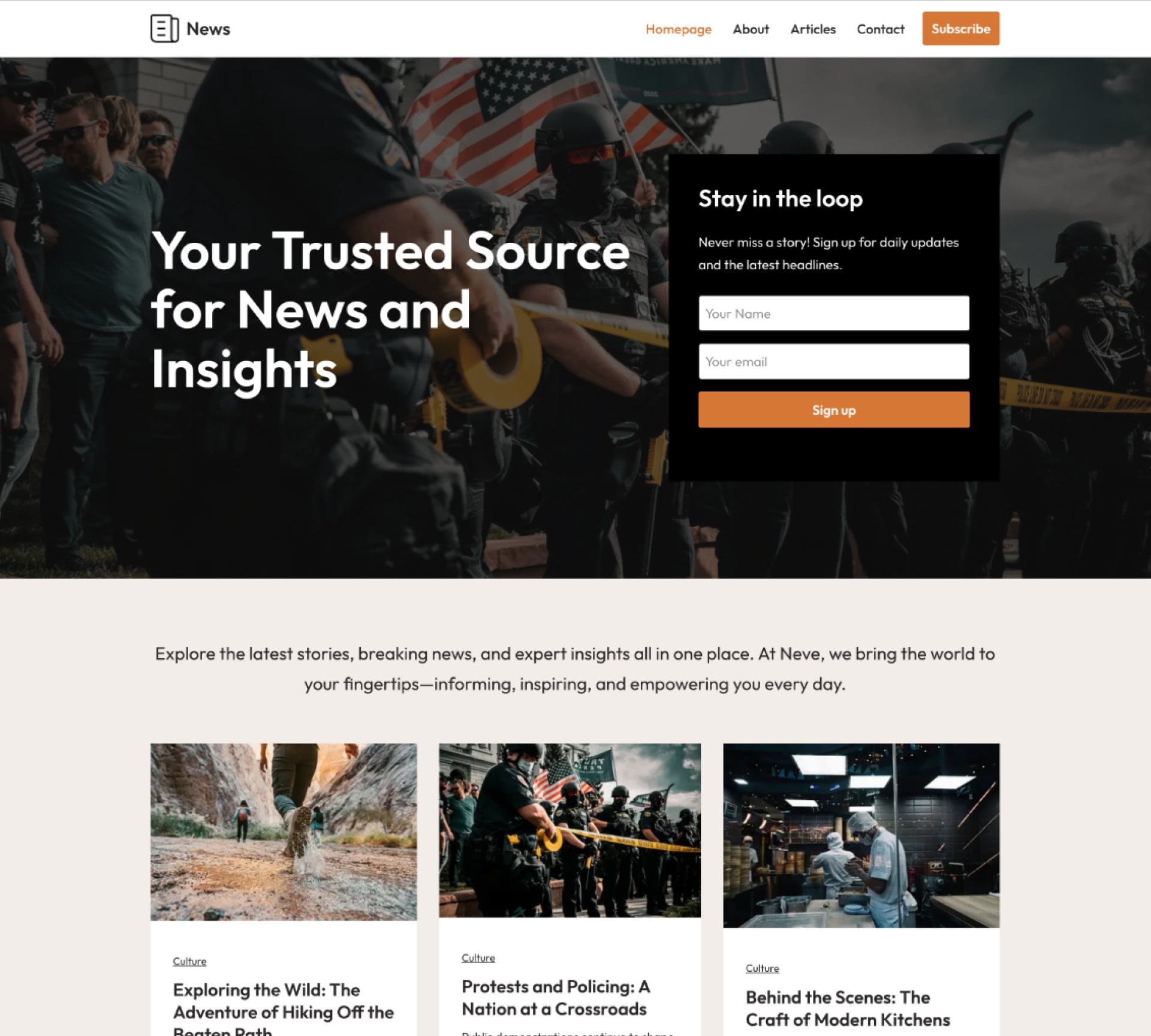

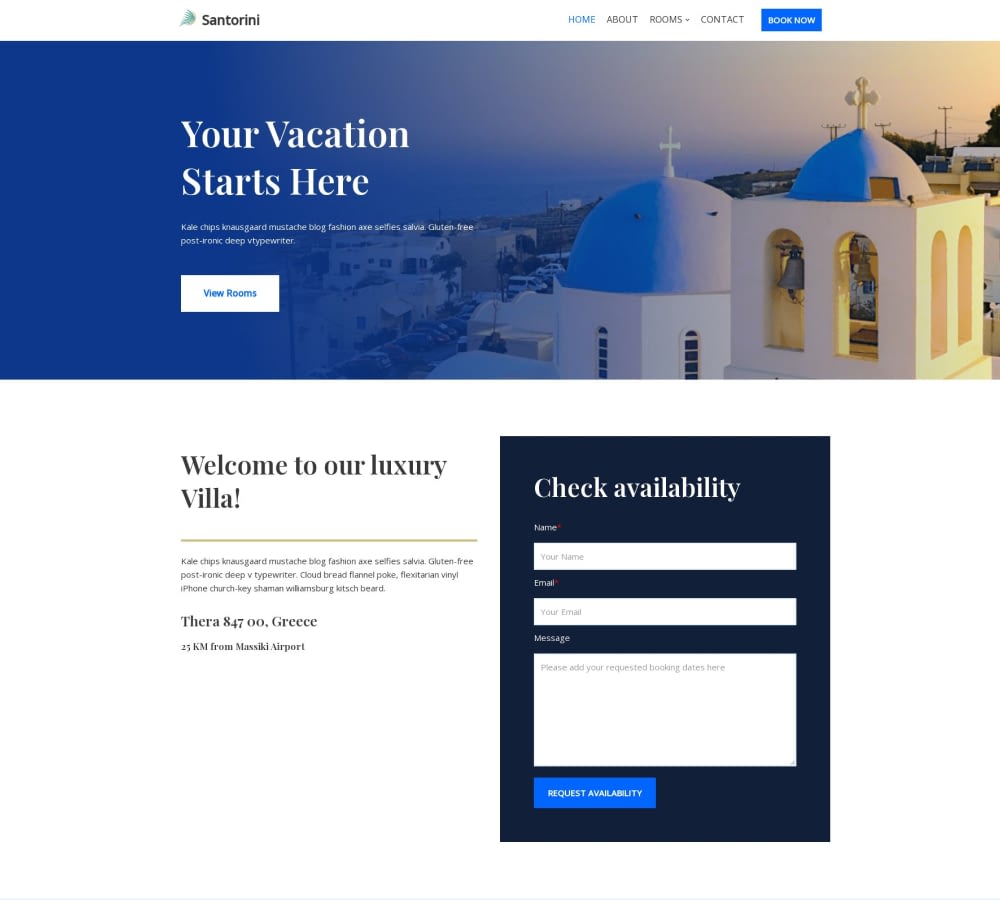

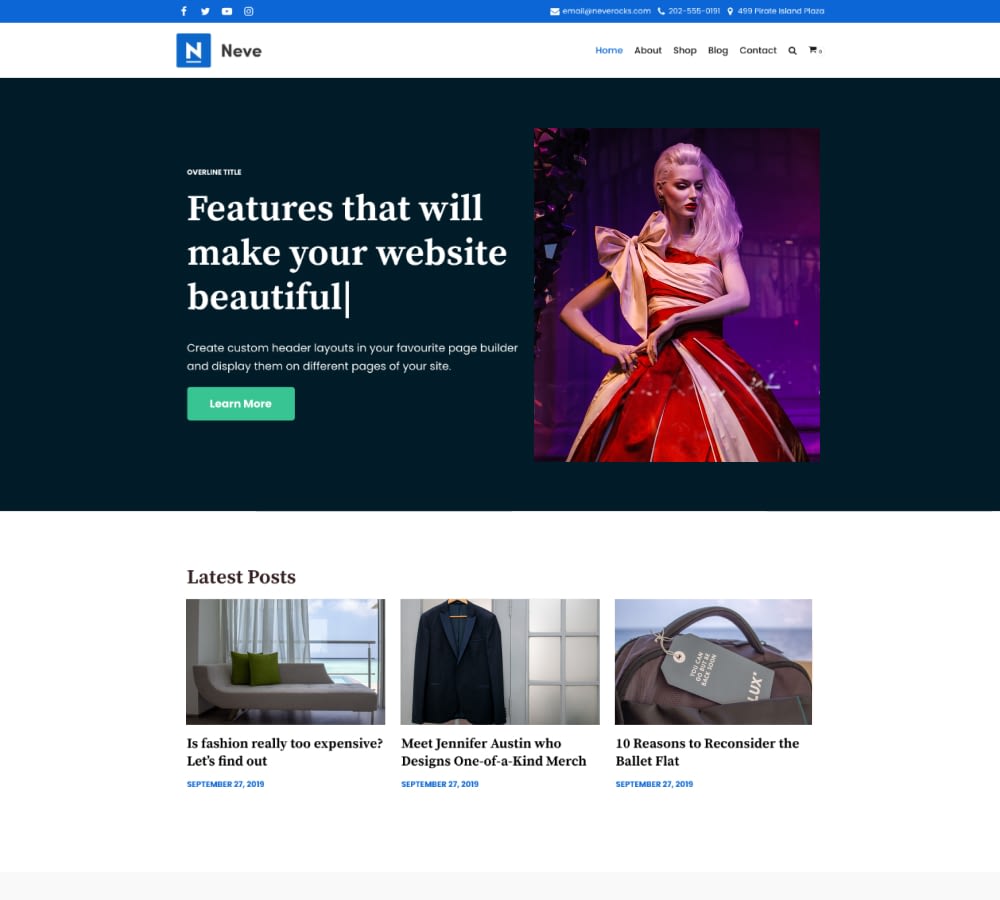

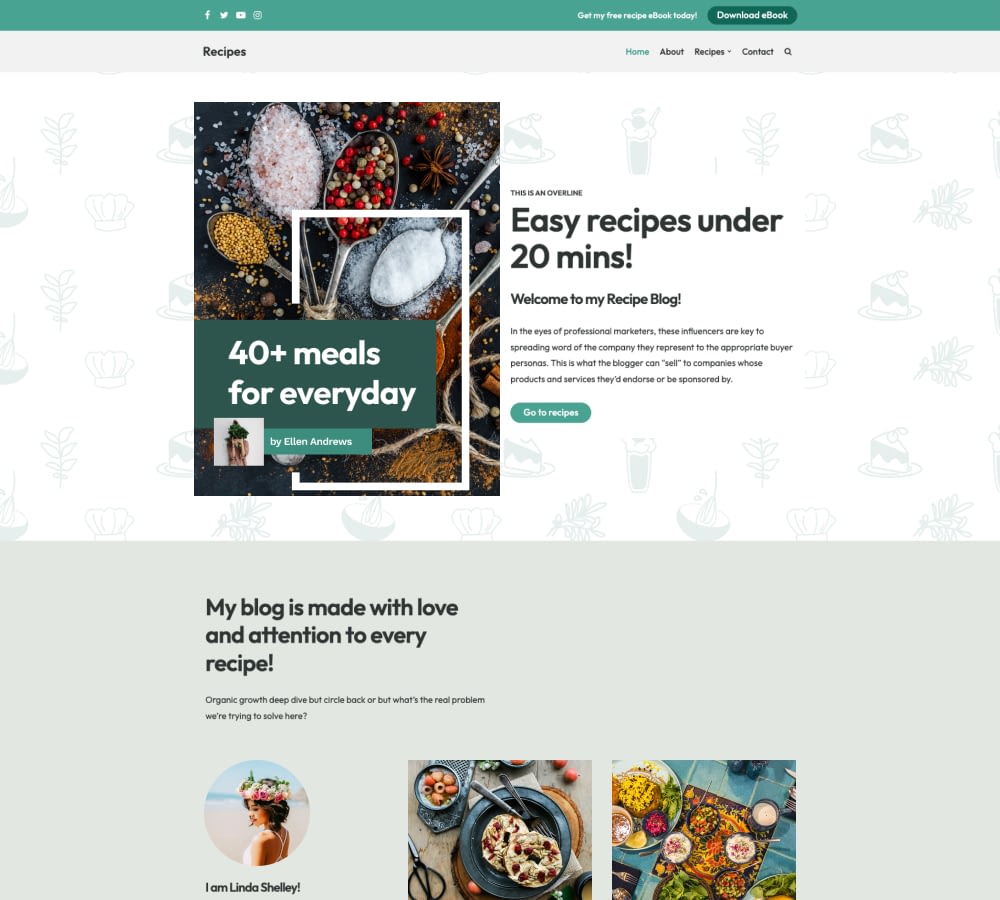

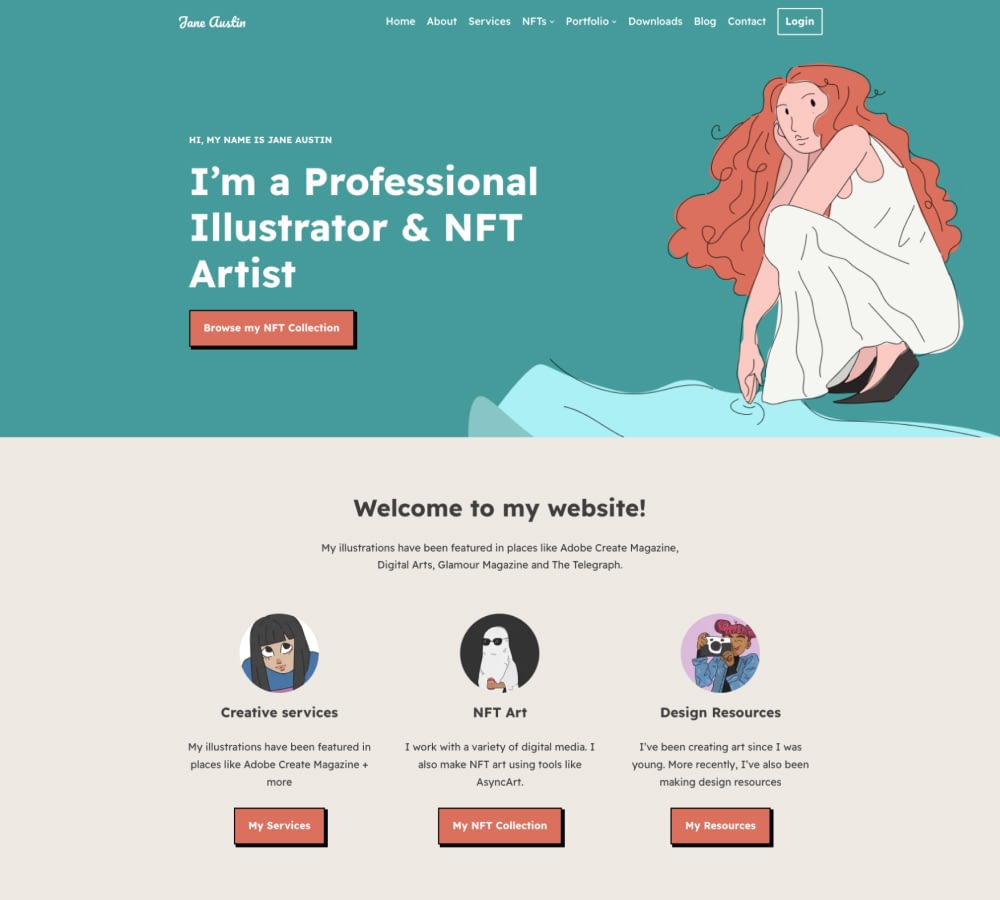

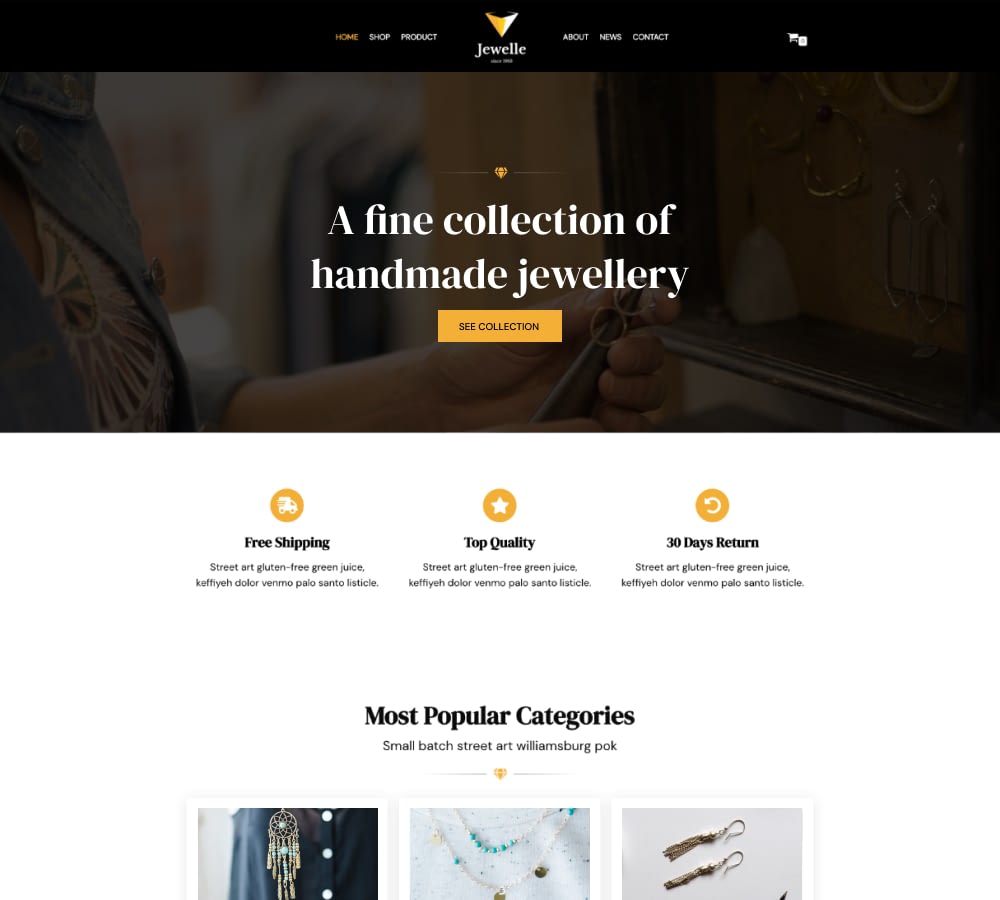

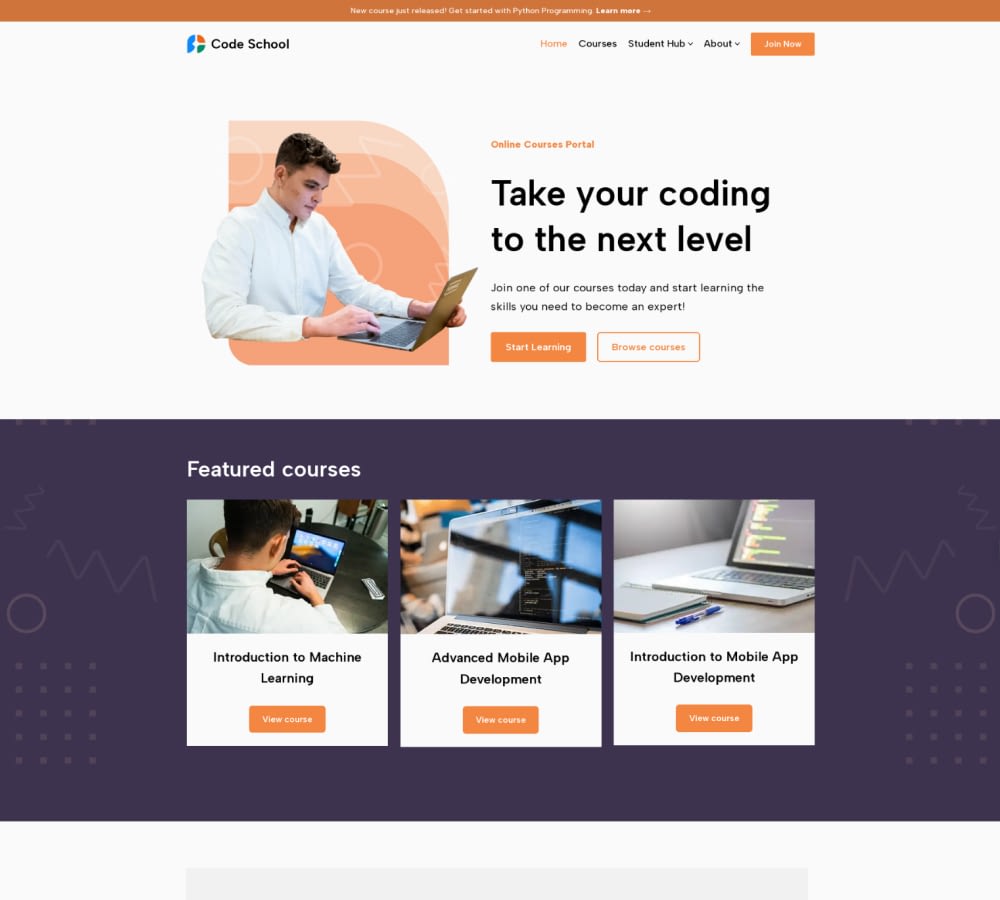

"We recently needed to overhaul our website and ThemeIsle provided all the resources we could have ever imagined. The templates are very elegant, very easy to use and manipulate. I can attest that our website views increased exponentially. We absolutely love ThemeIsle!"

Neal Newman – academyselfdefense.com